PLM, or Product Lifecycle Management, are comprehensive solutions that support product lifecycle management - from conception, through design and production, to recall.

PLM integrates people, processes, data and technology, enabling efficient and effective management of all aspects related to a product.

With PLM systems, companies can integrate the different phases of the product lifecycle, leading to better workflow, reduced time-to-market and increased quality of the products offered.

The importance of PLM systems

PLM systems are becoming an indispensable tool for companies wishing to keep their supply chains in order. Modern business requires rapid response to change, efficient management of resources and minimization of risk. PLM systems allow to:

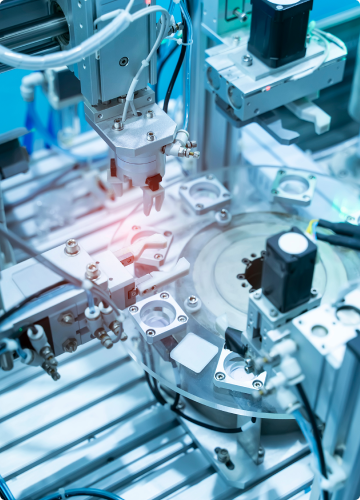

- Optimize manufacturing processes: By better organizing data and processes, companies can reduce the time it takes to develop a product and bring it to market.

- Improve collaboration: PLM facilitates communication and collaboration between different company departments, leading to a better understanding of needs and requirements at each stage of the product life cycle.

- Cost reduction: By automating processes and better managing data, companies can reduce costs associated with errors, overproduction and waste.

- Increased innovation: PLM systems support creative and innovative processes, enabling rapid prototyping and testing of new ideas.

All of these elements make PLM class systems a recipe for success in the manufacturing and trade industry, enabling companies to not only maintain, but increase their competitiveness in the global market.

PLM systems functions

PLM systems offer a wide range of functions and elements that support product lifecycle management at every stage. Here are the most important ones:

PLM systems integrate core functions of data, process and project management, ensuring consistency and efficiency throughout the product lifecycle.

They enable companies to better manage resources, increase innovation and maintain the quality of their products, which is an indispensable element for success in today's market.

Benefits of PLM implementation

Improved process efficiency

Implementation of PLM system significantly improves the efficiency of business processes through automation of tasks, better organization of work and integration of various departments within the company, enabling smoother cooperation and coordination of activities.

Optimization of product data management

PLM systems optimize product data management. All product information is stored in a single, easily accessible place, eliminating the problem of duplicate and outdated data. In addition, employees have quick access to the information they need, speeding up decision-making and task completion.

Reduce costs and shorten the product life cycle

Automation of production processes and better data management reduce the number of errors and the need to correct them, which reduces operating costs. Product launches become much faster thanks to better workflow. Besides, PLM enables more efficient use of human and material resources, which translates into lower production costs.

Modern PLM systems such as SilkPLM also increase companies' flexibility, enabling faster prototyping or testing of new ideas. What's more, with easy access to information, teams working on a product can react quickly to market trends, making them more competitive in a rapidly changing market.

Our PLM services - What can we do for you?

We offer a comprehensive approach, from consultation and needs analysis, to solution design and customization, to integration and technical support. As a result, you can be sure that your PLM solutions will be effective, consistent and fully tailored to the specific needs of your business.

Consultation and needs analysis

We conduct a detailed analysis of your company's needs to understand the specifics of your business and your expectations from PLM system. We will also assess your current product lifecycle management processes, identifying areas for optimization.

Design and customization of PLM solutions

We design PLM solutions that are perfectly tailored to your company's specific needs, and conduct thorough testing of the proposed solutions to make sure they meet all requirements and expectations.

Integration of PLM systems with existing processes and tools

We integrate PLM systems with your existing systems, and ensure seamless data migration from legacy systems to new PLM solutions, minimizing the risk of data loss.

Training and technical support

We organize training courses for employees to take full advantage of PLM systems capabilities. We provide regular system updates and development of new features to ensure that PLM system always meets the latest standards and market needs.